Our Services

What We Offer

LEL Nuclear provides an extensive array of services encompassing Mechanical, Nuclear, Electrical, and Industrial Engineering. Our on-site teams are here to support all your project needs. We offer comprehensive turnkey solutions for equipment removal and installation.

At LEL Nuclear, we possess the capabilities and resources needed to customize packages to precisely match your specifications. Explore our comprehensive list of capabilities to determine if LEL Nuclear can be of service to you.

Don’t hesitate to reach out to our dedicated team for further assistance.

Tel: 01900 878010

Email: enquiries@lel.uk.com

Our Capabilities

- Mechanical Installations

- Mechanical Maintenance

- Electrical Installations

- Electrical Maintenance

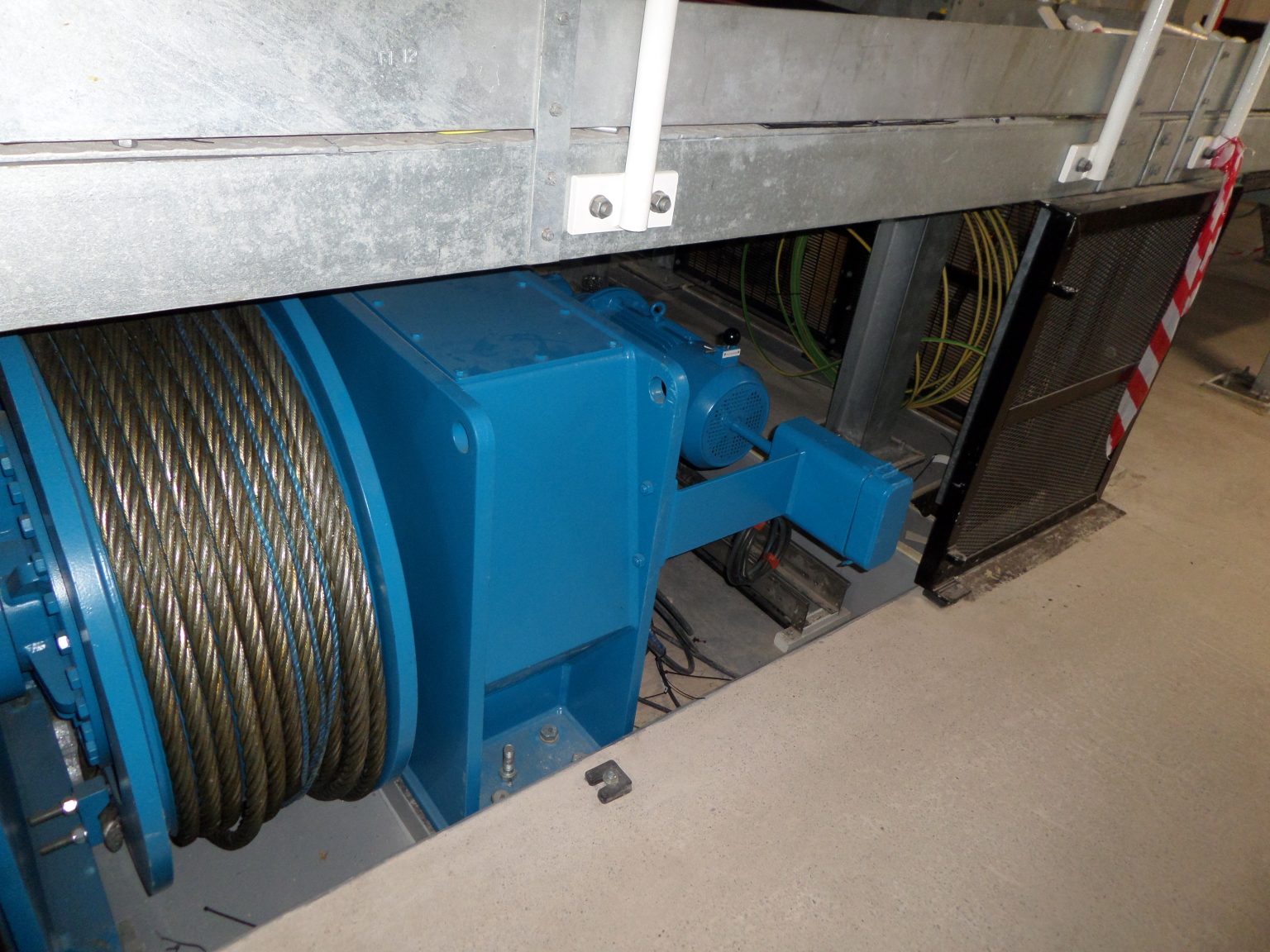

- Lifting and Rigging Operations

- EC&I, Fibre installations & Testing

- Commissioning & Decommissioning

- HVAC

- NDT Pull Testing

- Ferroxyl Testing

- Pipe Fitting

- Overhead Crane Maintenance & Inspection

- Overhead Crane Installation & Commissioning

- Steel Erection

- Pump and Valve Maintenance

- Steel/Alloy Platform manufacture & Installation

- Mechanical Installations.

- Mechanical Maintenance

- Plant Maintenance

- Nuclear Installations

- Shield Door Installations

- Shield Door Refurbishment

- Electrical Installations

- Pump & Valve Maintenance

- Area & Machine Guarding

- Ferroxyl Testing

- Commissioning

- Steam Trap Surveys

- Pressure Systems

- LOLER/PUWER 1998 Inspections

- Overhead Crane Maintenance & Inspections

- Overhead Crane Installation & Commissioning

- Manipulator Installation & Commissioning

- Steel/Alloy Platform manufacture & Installation

- Steel Erection

- Valve lapping & Grinding

- Site Gates Installation

Resources

Our team boasts a complete lineup of project managers, project engineers, and skilled personnel, including mechanical fitters, platers, riggers, electricians, commissioning experts, and more, all readily accessible to meet your needs.

Furthermore, we maintain state-of-the-art engineering workshop facilities that allow for equipment storage, pre-assembly, and factory acceptance testing before the equipment is delivered and installed as part of your projects. In cases where we may not be able to directly accommodate your requirements, our extensive local support network enables us to provide precision machining, turning, milling, and boring for equipment refurbishment, repair, or even custom manufacturing to fulfil your specific needs.